Our Journey So Far

Pre-2010

In the mid 2000s, Canadian geophysicist Brian Powell (then working for Cameco) was exploring the rugged Athabasca Basin in the Canadian Shield. He had learned about muon tomography from a documentary, as the science had been used since the 1950s to image tunnels, the Great Pyramids of Giza, and volcanoes.

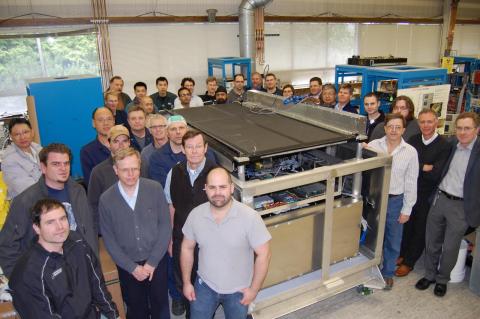

Inspired by the unique capabilities of the technique, Brian wondered whether it could be used for mineral exploration as well. He took his idea to the team at TRIUMF, Canada’s national particle physics laboratory, kickstarting an academic project. In the years to follow, the TRIUMF team developed and tested the world’s first muon detectors for subsurface mineral exploration.

2011-2012

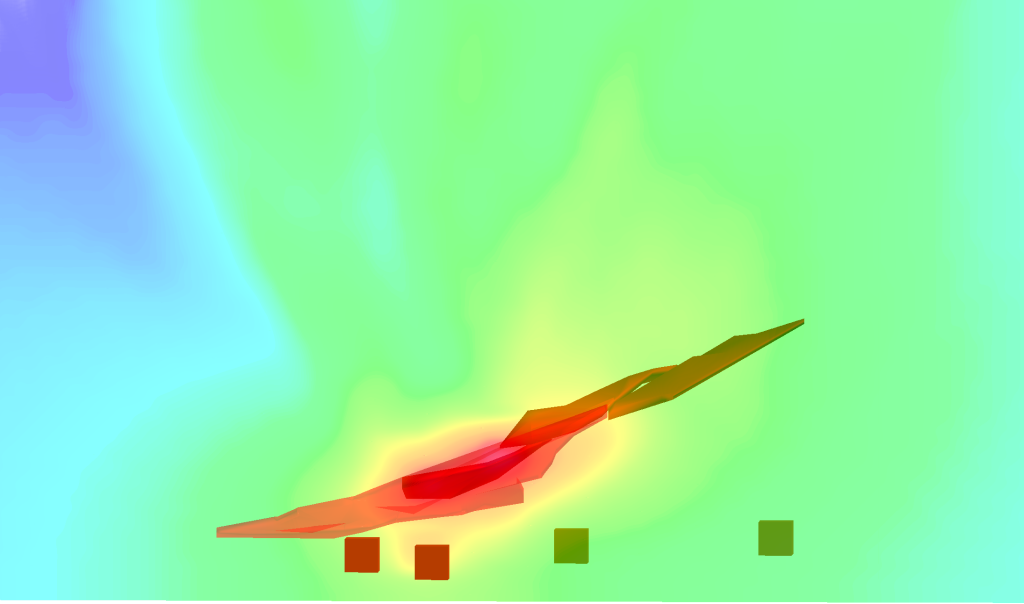

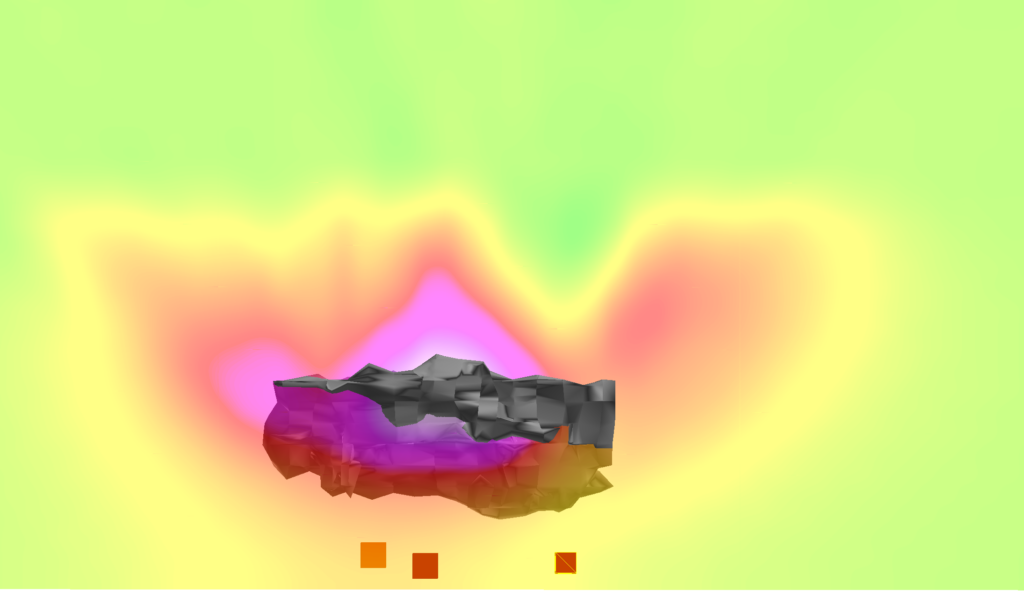

A successful proof of concept trial of muon tomography was conducted in 2010, imaging the Price deposit at the Myra Falls mine in British Columbia. The ore body is located under a provincial park in an environmentally sensitive area, preventing drilling from surface.

This volcanogenic massive sulfide (VMS) deposit contains zinc, copper, lead, and silver. Using muon detectors situated in-mine at a depth of about 300m (984 ft) in mountainous terrain, the Price deposit was mapped in 3D. This is the first known application of muon tomography for subsurface mineral exploration.

CRM Geotomography Technologies Inc. was founded in 2013 to advance the imaging solution towards commercialization.

2013-2018

The first production muon detectors built at TRIUMF were large (1m x 1m x 2m/3.3ft x 3.3ft x 6.6ft) and heavy, requiring significant logistical effort to deploy and limiting placement to in-mine drifts. An initial blind field trial was conducted at Teck’s Pend Oreille mine in Washington, USA, successfully imaging a Mississippi Valley-type (MVT) polymetallic deposit at ~500m/1640ft. A subsequent trial at Orano’s McArthur River mine in Saskatchewan, Canada successfully imaged a compact high-grade uranium deposit at ~600m/1969ft depth.

2019-2021

By 2019, the team had engaged BHP — the world’s largest mining company — for a blind field trial in Western Australia to image a high-grade nickel deposit. Just after deployment, the global pandemic struck, as Gary Agnew took the helm as Co-Founder & CEO. In May 2020, CRM Geotomography Technologies became Ideon Technologies and advanced a path to commercialization by closing C$1.3 million in seed funding a few months later.

By spring 2021, the team had completed a 50x miniaturization of the muon detector, and deployed the world’s first borehole-sized sensors at Orano’s McClean Lake, SK site that June. By year-end, Ideon had launched the Earth X-Ray for Low-Impact Mining project, together with the Digital Supercluster, Simon Fraser University, Dias Geophysical, Microsoft, Fireweed Metals, BHP, and Mitacs.

2022-2023

The momentum continued into 2022. Ideon rolled out an early-access program for the borehole muon detector with clients such as BHP, Glencore, NexGen Energy, and Fireweed Metals. In spring of that year, the team relocated to a larger space to keep pace with market demand.

By that time, Ideon could finally reveal that it had an active deployment on Oak Island, Nova Scotia as part of the History Channel’s long-running reality series, The Curse of Oak Island. In Sept 2022, Ideon announced a US$16 million/C$21 million Series A funding round, led by Silicon Valley deep-tech VC Playground Global.

As 2023 kicked off, Ideon deployed with Vale and was honoured with the Governor General’s Innovation Award.