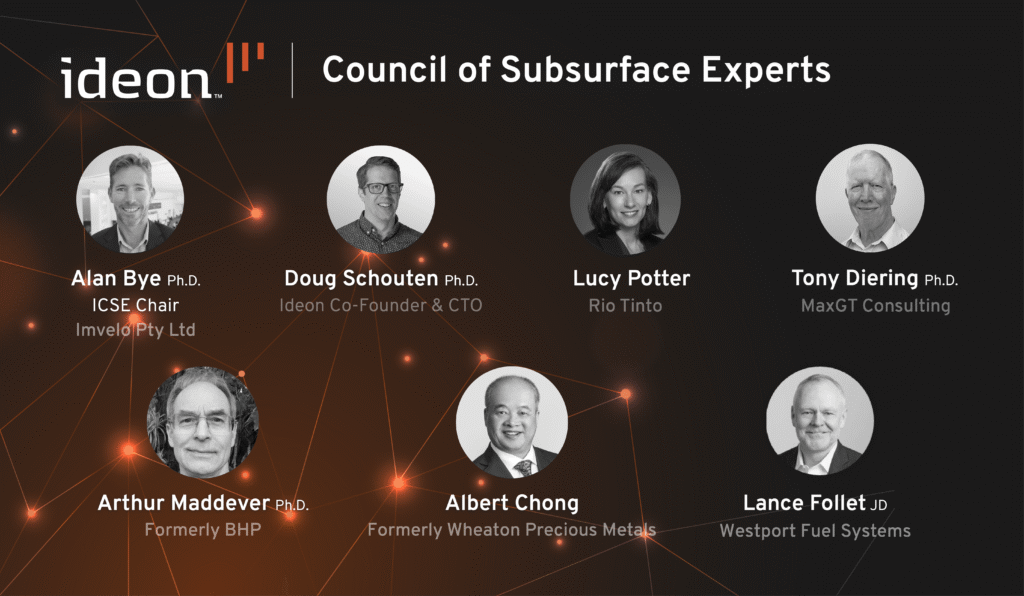

The Ideon Council of Subsurface Experts (ICSE) brings together seasoned experts from across the mining value chain to help Ideon address the industry’s most pressing subsurface challenges. As Chair of ICSE, Alan Bye, PhD brings over two decades of experience leading innovation across the sector – playing a pivotal role in driving the industry towards smarter, more sustainable technology-enabled operations.

In the first of six Q&A articles introducing ICSE members, Alan reflects on how innovation drives transformation across the mining value chain. He shares insights on the power of integrating people, processes, and technology to drive meaningful change – identifying what it takes to make mining operations more productive, efficient, and reliable.

This conversation has been edited for brevity and clarity.

Your career spans a wide range of roles and experiences within the mining industry. Looking back, what are some standout highlights or achievements that have shaped you as an industry leader?

I’ll answer that in two parts. The first is understanding where the challenges are in the mining industry, and then bringing the people, capital, and technology together to develop solutions through R&D projects. The second is around operationalizing technology. I’ve worked on many sites around the world where we’ve taken an underperforming operation and implemented new technology to address some challenges they face. This has been extremely rewarding for me.

As an ICSE member, how do you see your role in helping guide the mining industry towards greater technological innovation?

Having worked in operations and in R&D, I have a holistic understanding of the challenges in the industry. I see my role as mobilizing the effort and bringing the people, capital, and technology together to solve them in a prioritized way. There are many things we can work on, but it’s crucial we target the most important operational drivers.

What do you see as the biggest challenges the industry is facing?

It’s a confluence of issues. Operationally, we’re seeing declining quality of resources, increasing energy costs, talent that is not attracted to the industry, and a large part of the workforce nearing retirement. There are also geopolitical influences on supply chains.

One way we can get through some of these challenges is to make our operations more productive. It’s a system-level challenge – the industry needs to be more efficient to drive our cost base down and ultimately produce more with less. There isn’t one single solution that can solve all operational challenges, but it ultimately starts with the ore body. If we don’t have a fundamental understanding of the ore body being mined, the problems compound downstream in the value chain. Technologies that help us deeply understand and characterize the ore bodies, the variability, and the risks, are fundamental.

How has your perspective on system-level transformation evolved over time?

I’ve learned that point solutions don’t work. They’re not sustainable. We may fix a small problem for a short period of time, but it eventually comes undone. Having a system-level view of your business and enabling a transformation program is essential.

How do you think leaders can leverage automation technology to ensure more efficient mining practices?

Automation technology needs a strong business case for where it could add value. It’s a case of prioritizing where you choose to deploy it, because each site has a different need. Technology is only one part of the solution. The processes, training, and skills of the people involved are crucial for it to work effectively. You cannot do this without thinking holistically about how people and processes work together with the technology. Unfortunately, I’ve seen many cases where it wasn’t integrated properly, and good technologies have failed because we haven’t done the people and process side of the equation.

What would be your #1 tip for building a clear communication strategy for people who are working on automation?

Understand mineral economics and be very clear on how automation would specifically benefit their mining business. If you start with a well-rounded business case that understands the value drivers, the people processing systems can work to deliver on that outcome.

As the pace of mining innovation continues to accelerate, what technological developments give you the most confidence in the industry’s ability to operate smarter and more efficiently?

There is a very exciting future ahead for the mining industry. The most transformative change will come from developing a unified technology stack. With new sensors coming into the industry, the challenge is in building AI on top of those sensors and integrating machine automation into a complete solution. Technology solutions are being developed at a rapid rate, so, it’s really a question of how quickly the industry adopts these technologies. From my perspective, the tools to transform the industry are available.

Given that the tools already exist, what key shift is needed to accelerate real transformation?

The constraint is mostly a belief or trust that these tools work. If you’re a busy general manager and someone says, “I have some tools that will help your asset be more productive,” your first question is naturally, “How do I know it works?”

There are gaps in terms of testing, de-risking, and proving that these technologies work. If we can prove that they are reliable and effective, and compress the time it takes to do so, then we should see an increase in the pace of adoption.