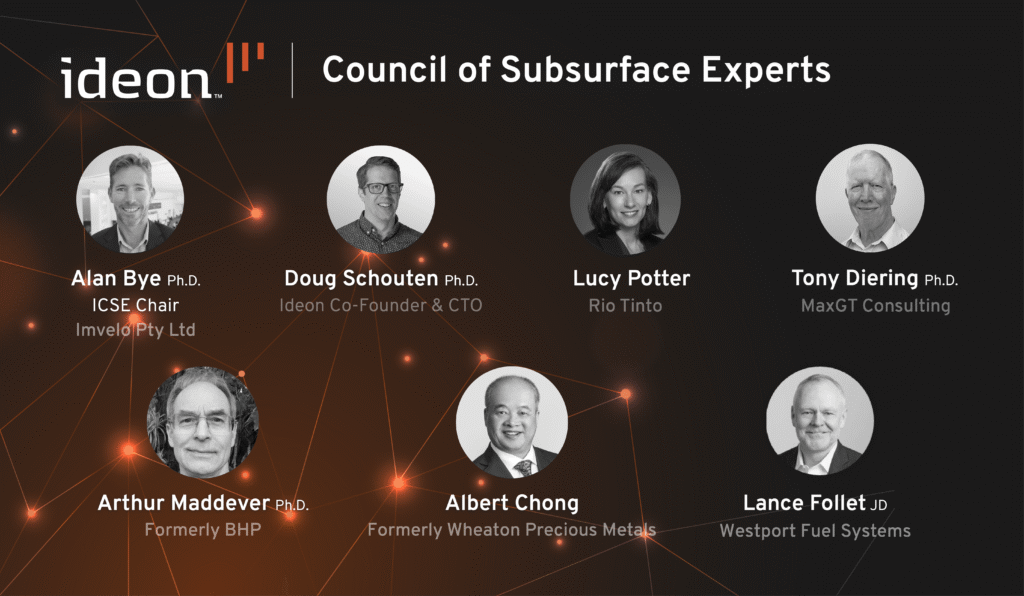

The Ideon Council of Subsurface Experts (ICSE) brings together seasoned experts from across the mining value chain to help Ideon address the industry’s most pressing subsurface challenges. As a world-renowned expert in cave mining, Tony Diering, PhD brings over three decades of experience in developing simulation tools and software suites that have helped shape how modern underground mines are designed and operated.

In the second article of our series introducing ICSE members, Tony discusses the growing role of cave mining, the geotechnical challenges that impact productivity, and the value Ideon brings to help advance these operations.

This conversation has been edited for brevity and clarity.

Your career spans a wide range of experiences. Looking back, what are some standout highlights or achievements in the caving domain that have shaped you as an industry leader?

Over three decades, I served as the principal developer of PCBC and PCSLC, which are specialized software applications widely used for planning and simulation of block and sub-level cave mining operations. My work began at SRK Consulting and then Gemcom Software International, where I led the further development of these systems. After moving to Dassault Systèmes, I oversaw and advised on their block and sub-level caving initiatives. Today, I continue to advance these efforts at MaxGT Consulting, the consulting firm I now operate alongside my son.

Another highlight of my career was being inducted into the Mining Technology Hall of Fame in 2015. It was a privilege to see this work recognized for its contribution to the industry. I also acted as an external examiner for graduate students at University of British Columbia, where I was later appointed Adjunct Professor for several years.

As an ICSE member, how do you see your role in helping inform the future of cave mining towards safer, more predictable, and higher performing operations?

I believe Ideon is addressing a fundamental gap in the industry, particularly in advancing geotechnical understanding and risk mitigation. My focus as an ICSE member is in the broader implications for mine planning and forecasting. The ability to accurately understand a cave’s behaviour and predict what it will produce is essential for effective decision-making. As these technologies continue to evolve, I see my role as offering high-level guidance and context in these areas to Ideon.

What initially motivated your focus on block caving?

In many ways, my involvement in the field has been a natural evolution. When I left university, I started working in an underground mine in the field of rock-burst research and helped develop software that models the stresses contributing to seismicity.

I expanded that work through developing software for 3D modelling of underground excavations. As there are significant overlaps between excavation behaviour and cave-back mechanics, this research naturally brought me into the sphere of block caving. Through that, I began collaborating with Dennis Laubscher, who is widely regarded as the father of modern block cave mining. The experience I gained during that period proved highly relevant to understanding and advancing block cave mining methods.

Which emerging technologies do you think will help inform more confident decisions in cave operations?

I truly believe the technology Ideon is developing is transformative for cave operations. Modelling in cave mining has always been challenging because of the lack of visibility inside of the cave. If you compare it to an open pit mine – where there is a direct line-of-sight of the orebody – caving without this visibility is like mining while blindfolded. Even with advances in modelling techniques, there is still a fundamental gap between what we think is happening, and what is unfolding underground. Ideon addresses this uncertainty by providing a 3D view of the subsurface across time periods, fundamentally reshaping how we understand and manage cave behaviour.

Considering the current state of the mining industry – increased productivity demand and delayed pace of recovery – do you anticipate that caving will become more widely adopted?

Yes, caving is expected to become increasingly prevalent, largely out of necessity. As we explore deposits that extend deeper underground, the volume of waste rock accumulates – leading to larger waste dumps, increased costs, and reduced overall productivity. For this reason, the long-term prospects for open pit mining are limited, especially in the context of mining for high-grade deposits. These orebodies often lie deeper underground, and when they are both extensive and continuous, the economic and technical case for caving becomes compelling.

Caving also demonstrates a strong safety record relative to other underground mining methods. As a result, it repeatedly proves to be the most effective, and in many cases, the only viable means of extraction.

As caving becomes more prevalent, do you think the industry has the necessary depth of expertise to sustain and advance these operations?

I believe the industry will continually renew itself. New professionals are entering the field with strong technical capabilities and fresh perspectives. As with any specialized discipline, there is a learning curve, but the talent pipeline is healthy. Overall, I don’t see it as a critical scarcity, because knowledge transfers and new talent emerges.