A looming supply gap in critical minerals is putting the mining industry in the spotlight. Our industry is under tremendous pressure to deliver quickly — and to do it with less cost, risk, and environmental impact.

Where will this new supply come from? Only a small fraction will come from recycling or new green-field discoveries. Even if the mineral exploration process were yielding suitable new supply (and it is not — discoveries are down 75% with –45% return on investment over the past decade), the average time from initial exploration to mine production is still 16 years, with a 99.9% project failure rate. The conclusion is that the critical mineral resources the world requires to shift to clean energy quickly must come from existing mines.

Given humanity’s long-standing use of mineral and metal resources, most near-surface resources have already been recovered. Mining companies are searching deeper underground and revisiting historic sites to find new resources. From near-mine exploration through to mine planning and operations, mining companies stand to benefit from new technologies that allow them to understand the subsurface at great depths, and with higher resolution than ever before.

Canadian-made mining tech uses natural energy from space

The new technology uses naturally occurring energy from supernova explosions, in the form of subatomic particles called “muons,” to image deep beneath the Earth’s surface. The development and application of cosmic-ray muon tomography offers a subsurface intelligence platform — comprising proprietary detectors, dynamic data acquisition and integration, artificial intelligence, and 3D visualization — that helps mining companies map and monitor mineral deposits and other anomalies with precision and confidence.

Equipped with subsurface intelligence from beginning to end of the mining value chain, mining companies can improve critical metals recovery, reducing time to market, cost, risk, and environmental impact while optimizing their investments across the life of mine. When they understand the subsurface, with quantified measures of uncertainty, they can make risk-based and informed decisions that help them conduct targeted recovery and get critical minerals to market quickly. In so many parts of the mining value chain, unknown uncertainty is a paralyzing driver of slow-downs and corporate write-downs. The technology provider, Ideon, is already working with multiple global mining majors (including BHP, Rio Tinto, Glencore, and Vale) that see its technology as a game-changer.

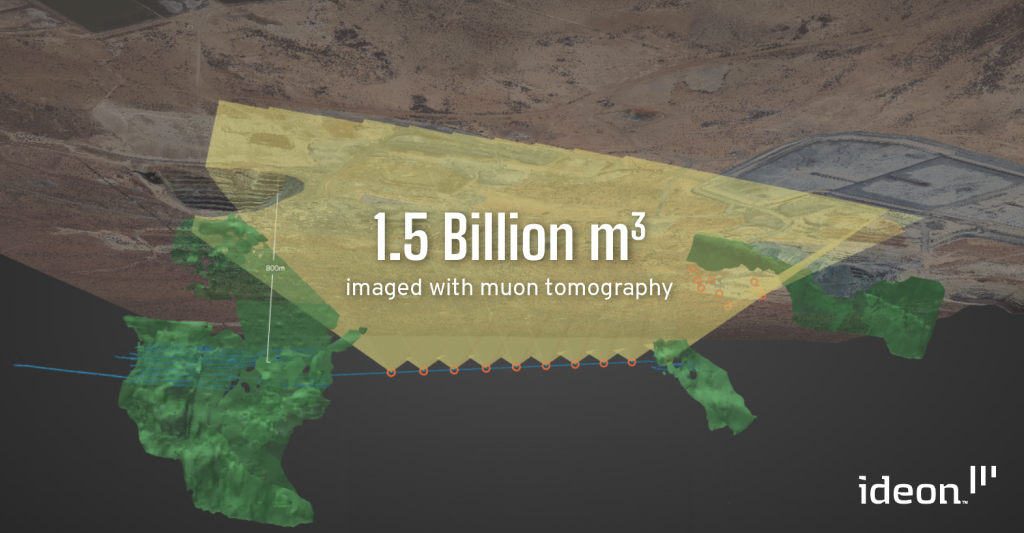

The survey layout at Leinster mine, showing in-mine and borehole detector locations, detector fields of view, and existing mineralization. The strike length explored was 3 km.

How muon tomography works

A good analogy to explain the technology is medical imaging. Medical imaging (such as X-ray and CT scans) uses an external energy source (radiation) to image non-invasively inside the body. Bones stand out very clearly because of the density contrast with the tissue surrounding them. Precision imaging like this allows medical professionals to conduct minimally invasive surgery. The technology uses the same principle in our application of muon tomography, harnessing cosmic-ray muons as a safe and naturally occurring energy source to image the Earth’s subsurface in 2D and 3D. Anomalies such as mineral deposits and subsurface voids stand out because of their density contrast with the surrounding rock. Precision imaging of the subsurface allows mining professionals to mine with fewer delays, less cost, and less waste, and mitigate targeted geotechnical risks in the subsurface.

Cosmic-ray muons are charged elementary particles that arise naturally from cosmic radiation interacting with the Earth’s upper atmosphere. Showers of muons bombard Earth steadily and are attenuated by the muon interactions with matter along their trajectory. Muons can penetrate deep into the Earth’s crust, down to thousands of metres, and their attenuation in matter is proportional to the density of material the muon passes through.

By measuring muon flux through detectors positioned beneath the surface, we can determine the average density in the overburden within a wide field of view above each detector. Each detector produces a radiographic image of the rock mass above it, and combining these images enables three-dimensional tomographic reconstructions of subsurface density. Rock density models derived via muon tomography can be used in a wide variety of settings from exploration and resource characterization to void mapping and monitoring of key operational workflows.

Case study: Muon tomography for nickel sulfide exploration at BHP

The muon tomography has been successfully deployed on multiple sites to map MVT and VMS-type base metal deposits, as well as unconformity-hosted uranium deposits. BHP Nickel West leveraged this capability to successfully image massive sulfide deposits over a 3-km strike extent in Western Australia. We imaged 1.5 billion m3 of the subsurface with no additional drilling, delivering metre-scale resolution of both high- and low-density anomalies — unlocking low cost, high-resolution prospecting and ore body mapping.

Leinster Mine is situated in the Agnew-Wiluna greenstone belt in Western Australia and is wholly owned by BHP and operated by BHP’s Nickel West group. The mine complex hosts several sulfide ore bodies. An existing subsurface drive was an ideal location to deploy in-mine muon detectors and search the volume above the drive for undiscovered massive mineralization. Further to the north, mineralization was hypothesized to recur down-dip, and no subsurface workings were present in that area.

Two different muon-tracking detectors were used: an in-mine detector and a cylindrical borehole detector. In phases 1 and 2, in-mine detectors collected data at nine locations along an underground drive at vertical depths below 800 metre. In phase 3, borehole detectors were installed to the north to explore an exploration target zone at downhole depths ranging from 200 to 400 metre.

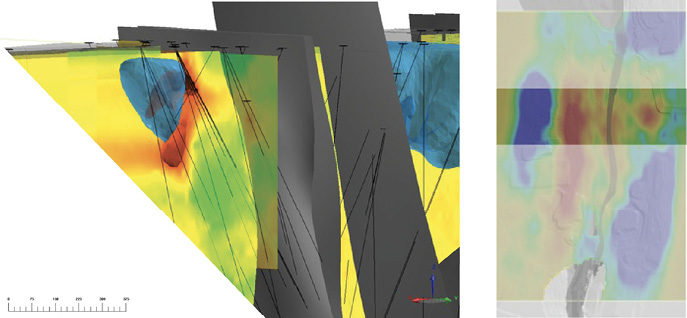

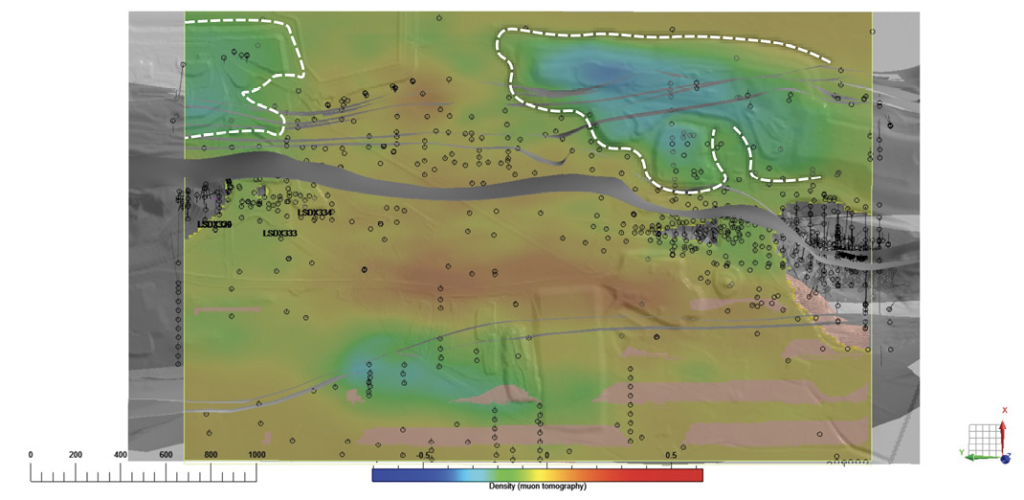

The average rock density was directly measured in each direction within the detectors’ fields of view. Data analysis was conducted remotely in Canada to verify quality and calibration, and to develop radiographic images of subsurface density and a high-resolution muon model of the region. A provided airborne gravity gradient and ground gravity data were used to perform multi-physics analysis and inversion, delivering a robust, unified 3D density model of the Leinster area.

The program successfully mapped well-known superficial features with few-metre lateral resolution from muon detectors positioned almost a kilometre below the surface and successfully resolved small regions of massive sulfide. Areas with high density were qualified with confidence intervals, and a >95% confidence level was ascribed to important massive sulfide and geological targets. The analysis also revealed voids from mining in the area, showcasing the utility of the technique for geotechnical applications.

The regional geology was mapped in high resolution, with almost no ground disturbance and minimal operational overhead on the mine.

The whole analysis was performed blind without imposition of geological constraints — showcasing the potential of muon tomography for use in mine-scale geological mapping, ore delineation, and brown-field exploration. BHP subsequently engaged Ideon to deploy muon tomography at Olympic Dam, one of the world’s most significant deposits of copper, gold, silver, and uranium.

A massive sulfide structure, revealed in drill data and shown in the interpolated density model derived from drilling with East-West and North-South slices shown along with a red iso-surface.

Leveraging technology to advance the clean energy transition

The muon technology is effectively de-risking critical mineral exploration and mining processes by quantifying geological uncertainty. With few ways to unambiguously know what lies beneath the Earth’s surface, most mining companies rely heavily on intensive drilling (at above-ground sites and in underground workings) to try and understand the subsurface, performing geological biopsies and inferring what may lie between those holes. Without geological certainty, these companies are basing billion-dollar decisions on fractional knowledge.

They are also continually advancing new mining techniques (such as subsurface caving) to unlock the potential of lower-grade critical mineral deposits, such as copper porphyry, but they do not yet have a complete set of tools to monitor and assess progress with confidence.

The ultimate challenge is to achieve better knowledge of and confidence in ore body characteristics, better informed mine planning, longer mine life, greater ability to leverage deposits previously considered inadequate, and more efficiencies across the entire mining value chain.

The new technology is addressing key knowledge gaps on mine sites — delivering certainty of understanding in an environment that has traditionally been very uncertain. Mining companies can drill less while mapping and characterizing more resources. As a result, they can make decisions faster, increase output while mining responsibly, reduce risk, save costs, and minimize environmental impact across the mining value chain.

Horizontal section of inverse density model, derived from muon tomography data at Leinster. The surface topography and main geological contacts, as well as drill hole collars, are shown in greyscale. A low-density contour (in white) aligns very well with a large waste dump of unconsolidated rock, and there is also good correlation with a shear zone that is the conduit for sulfide mobilization.